Biocut’s Aseptic Fluid Automation Solutions are custom designed for consolidating, automating and streamlining pharmaceutical processes with a central monitoring approach. We specialize in biopharmaceutical engineering and collaborate with the customer from the initial design concept to production. Biocut supplies and customizes all single-use equipment for continuous processing specific to your application.

Closed System Applications

-

- Filtration (Viral, TFF, UF/DF, Depth)

- Media Filling and Dispensing

- Chromatography

- Cell Culture/Bioreactor

- Gene Therapy

- Vaccine Production

- Mixing & Clarification

- mAbs Production

Automating Your Process

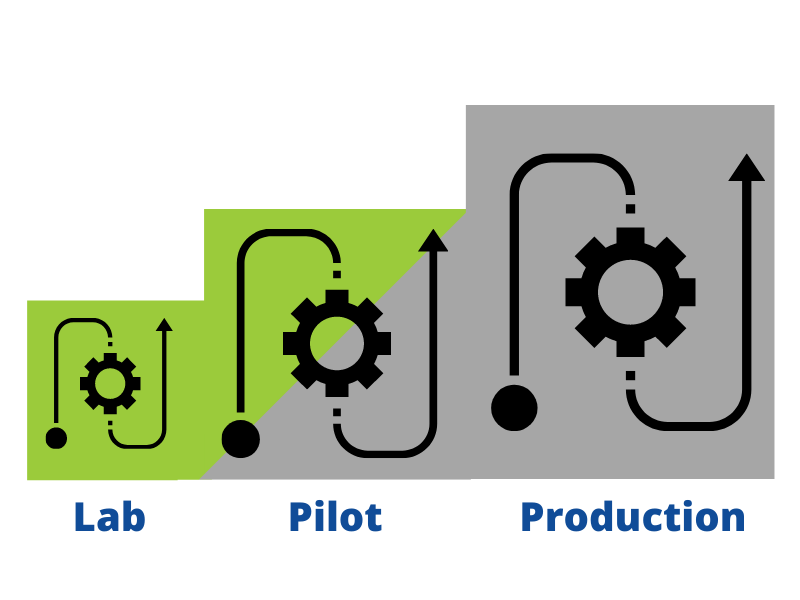

Bridging the Gap

Our new fluid handling technology can help aid in the transition between initial research/development and full scale production. Biocut is committed to customizing scalable systems to facilitate this transitional pilot phase.

Our Process

We are focused on developing customized automated systems for pharmaceutical processes. The most important part of our design and development is our foundational relationship with the customer to fully understand the problems they face and dive into the solution as a team.

- Align on Project Goals

- Ex) Data Logging, Validation, Quality Assurance, Space Requirements, Chemical and Material Compatibility

- Project Research

- Component Selection

- Software Development for Quality Assurance & Validation

- Component Integration

- Coding, Software Implementation and Data File Compilation

- In-House Biocut Testing and Programming

- Testing and Debugging on Site With Customer (IQ, OQ)

- Implementation at Facility (PQ)

- Documentation for Quality Purposes

- Establish Consumable Inventory